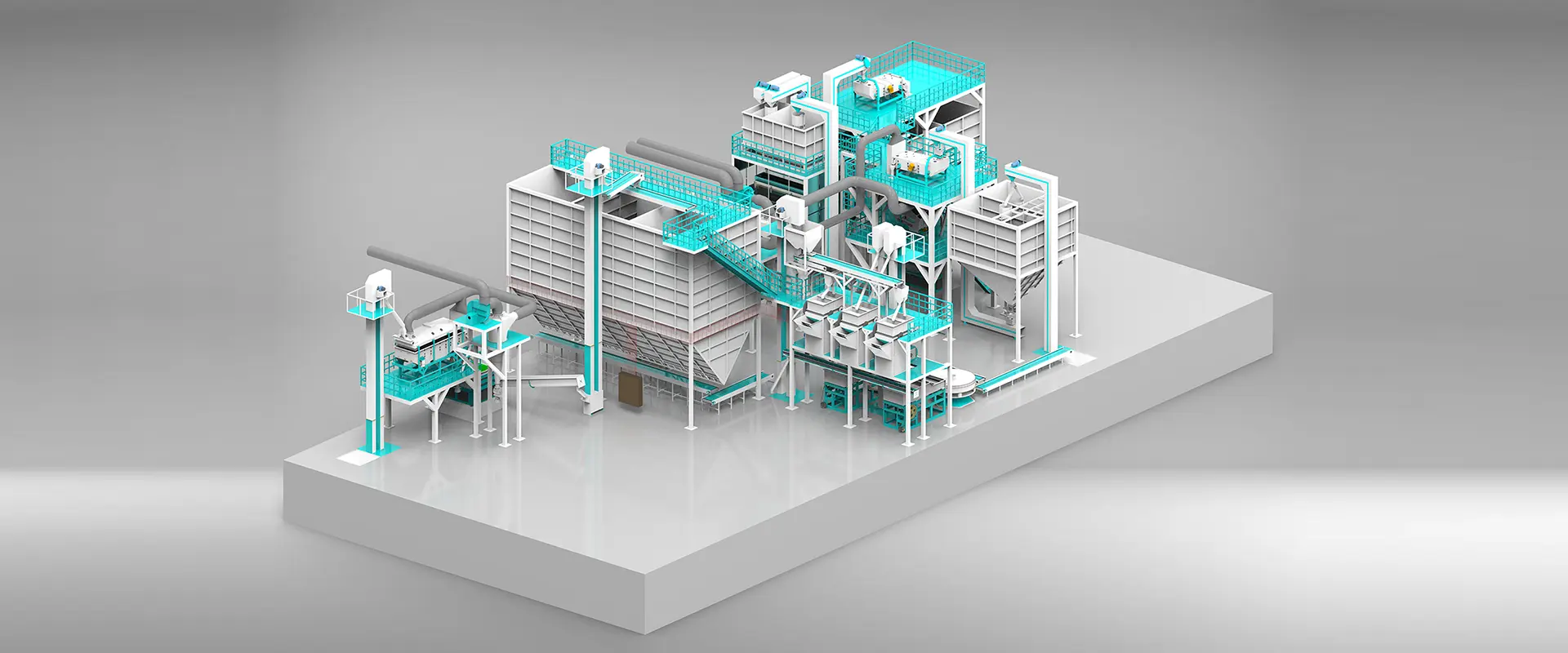

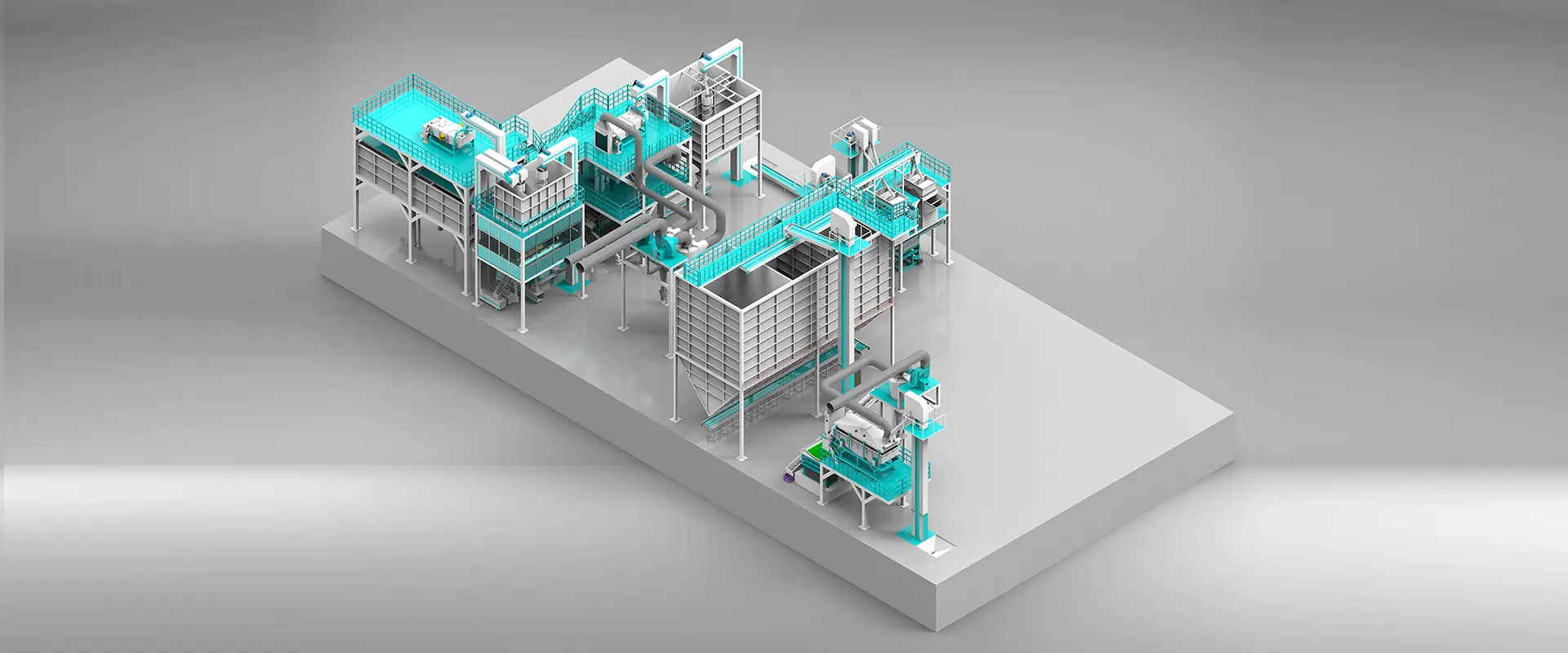

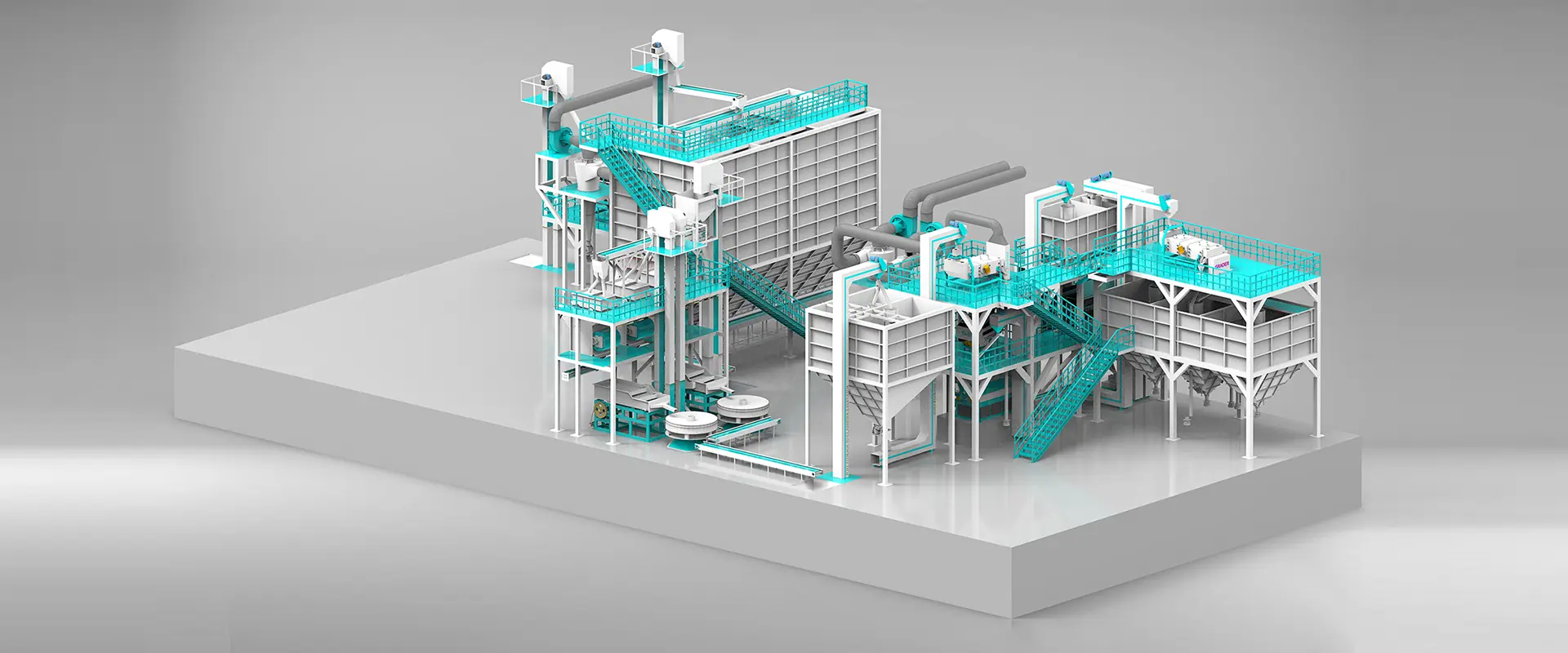

Groundnut processing plant is a revolutionary plant in the field of post-harvest processing industry, equipped with various hi-tech automated machines that helps in the wholesome cleaning along with de-shelling the groundnut, sorting and grading of the peanuts. The process starts with introducing the harvested groundnuts into the Pre-cleaning unit that is responsible for primary cleaning of the groundnut then it is stored for soaking up the moisture for 6-8 hours depending on the climate. After that it is conveyed to the De shelling unit for primary decortication. Later peanuts and smaller or Mono shelled whole groundnuts are separated by passing through Flat Screen Grader and Round grader back-to-back.

Smaller or mono shelled groundnuts are taken back for secondary decortication. Peanuts are transferred to the storage hopper for further processing. Peanuts are then passed through Classifier Machine to differentiate among the oversize, medium and small peanuts. Destoner Machine to separate out the denser impurities from the peanuts. All these machines are given a connection with Aspiration channel to suck and blow out the dust and light weight peels of peanut. Peanuts are then fed to the Gravity machine to separate the peanuts based on their weights, lighter and heavy materials lie on both the end and mixture of both lie in the middle, which needs to recycle in the Gravity Machine. Lastly peanuts are Color sorted in the Sortex machine then moves for Grading as per required count.

Groundnut Raw Material

Pre-cleaned Material

Deshelled Peanut

Classifier Accept Material

Gravity Accept Material

Sortex Output

Grader Output – 1

Grader Output – 2

Grader Output – 3

Peanuts’ value added products

Roasted Peanuts

Peanut Chikki

Peanut Butter