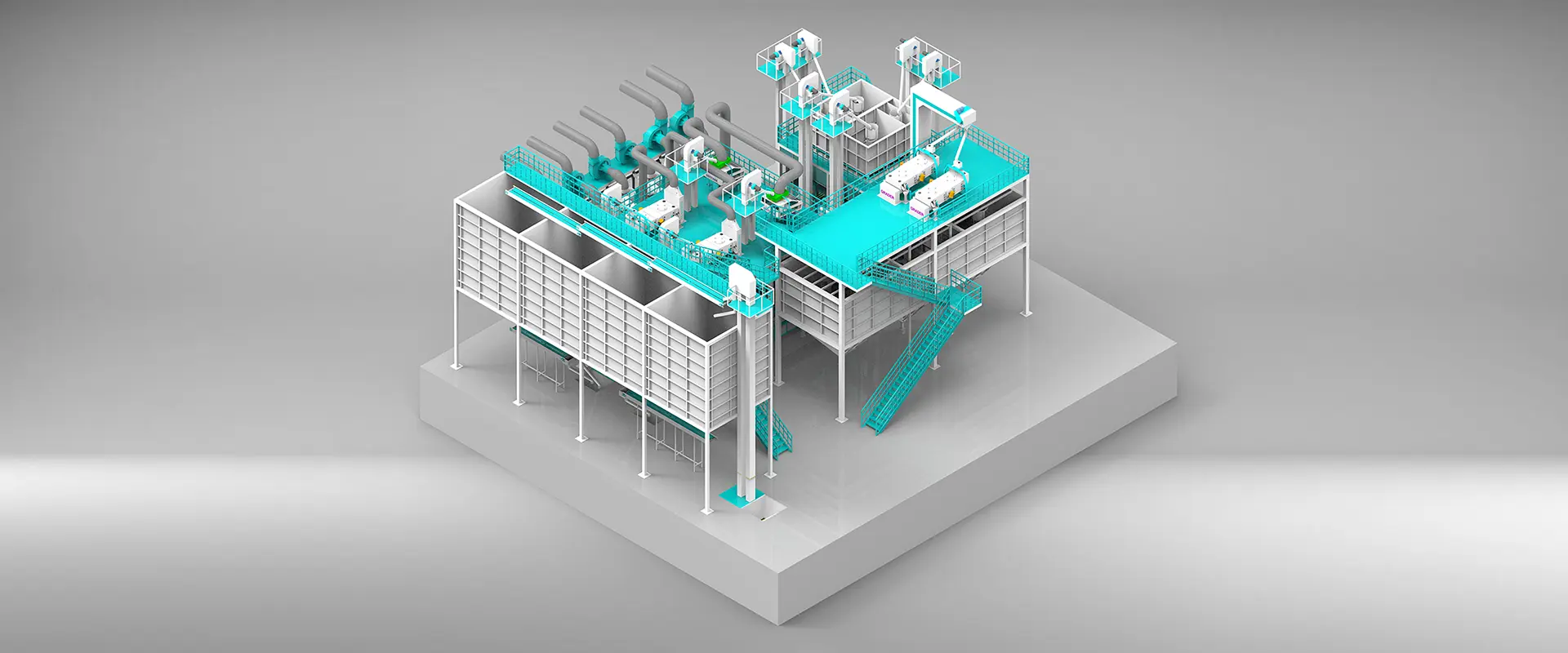

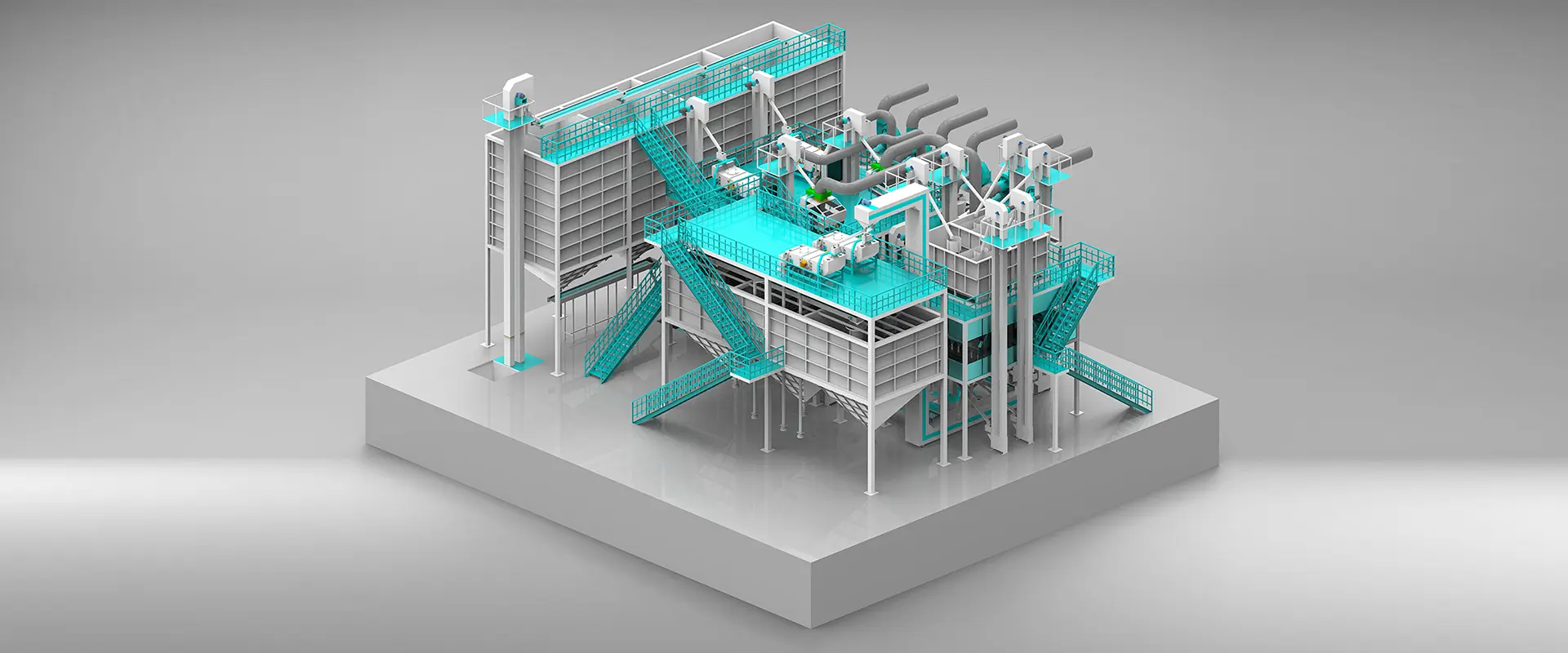

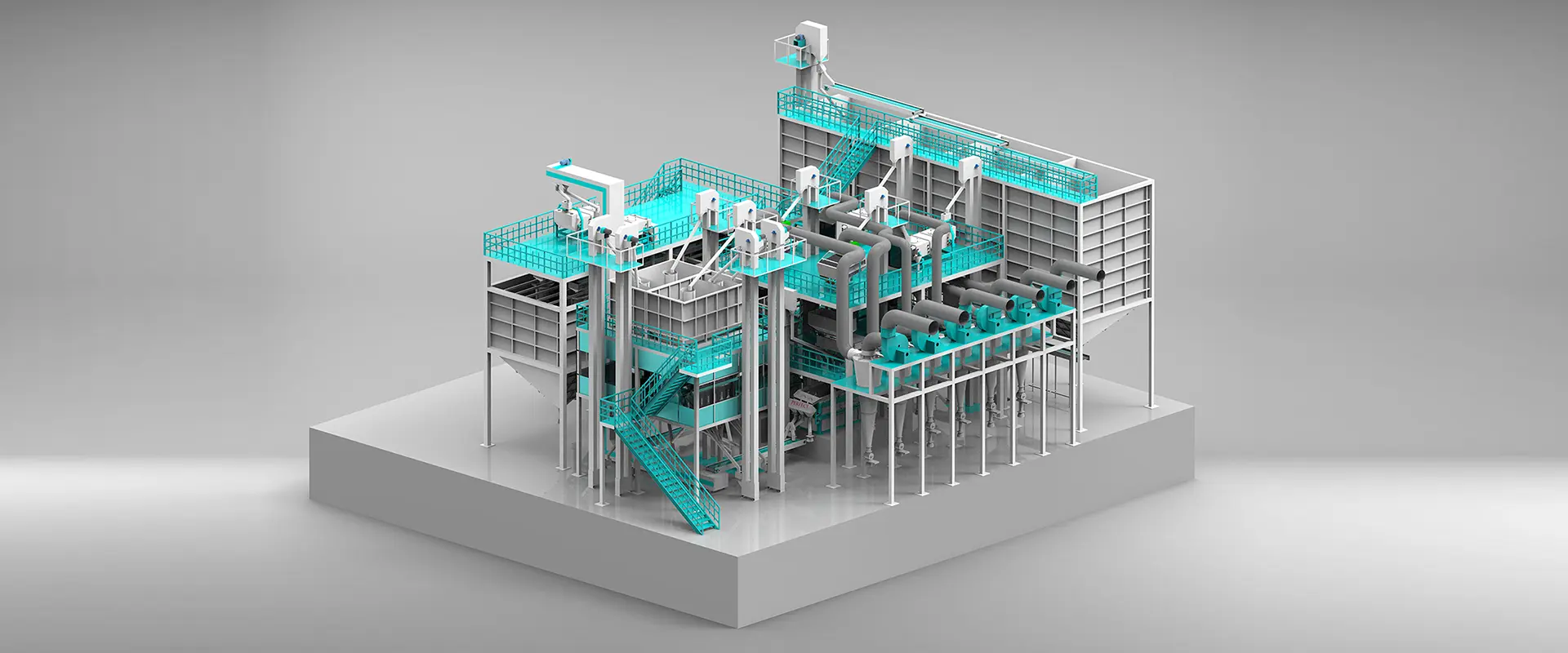

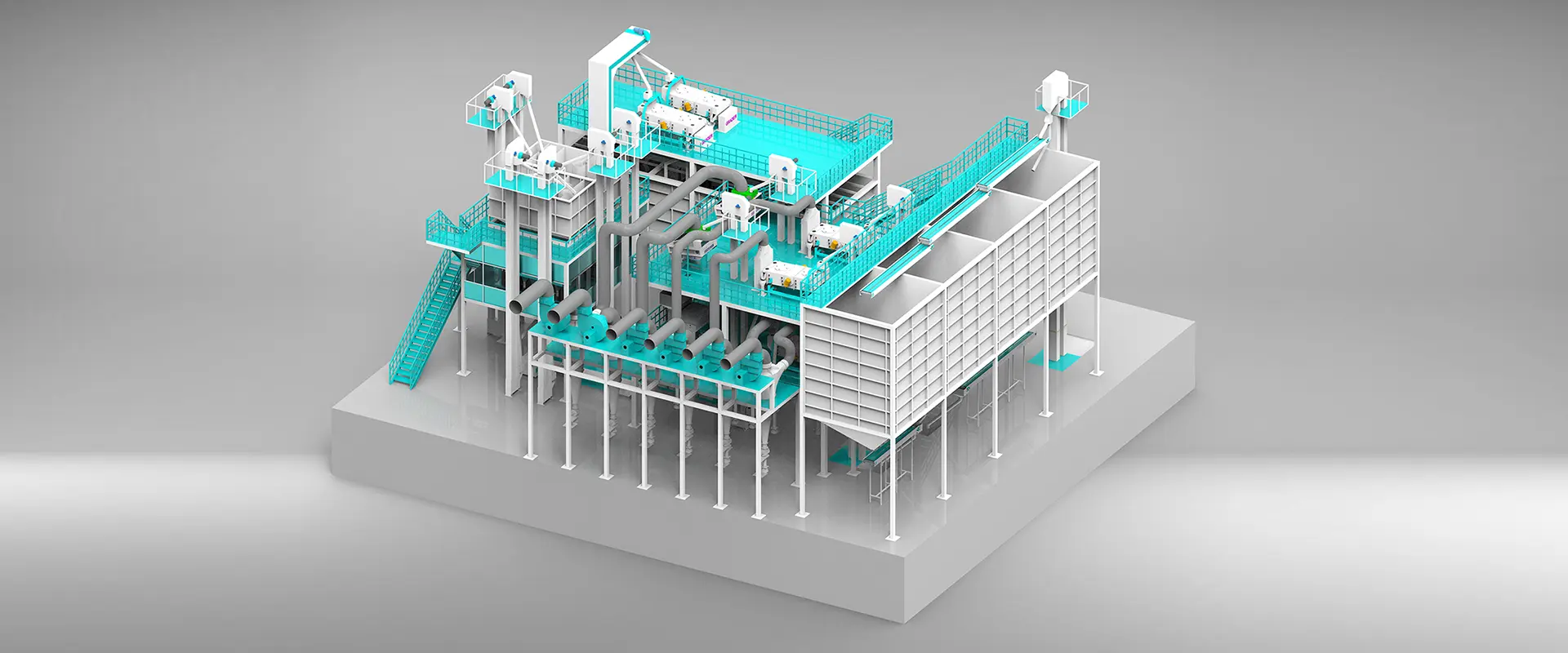

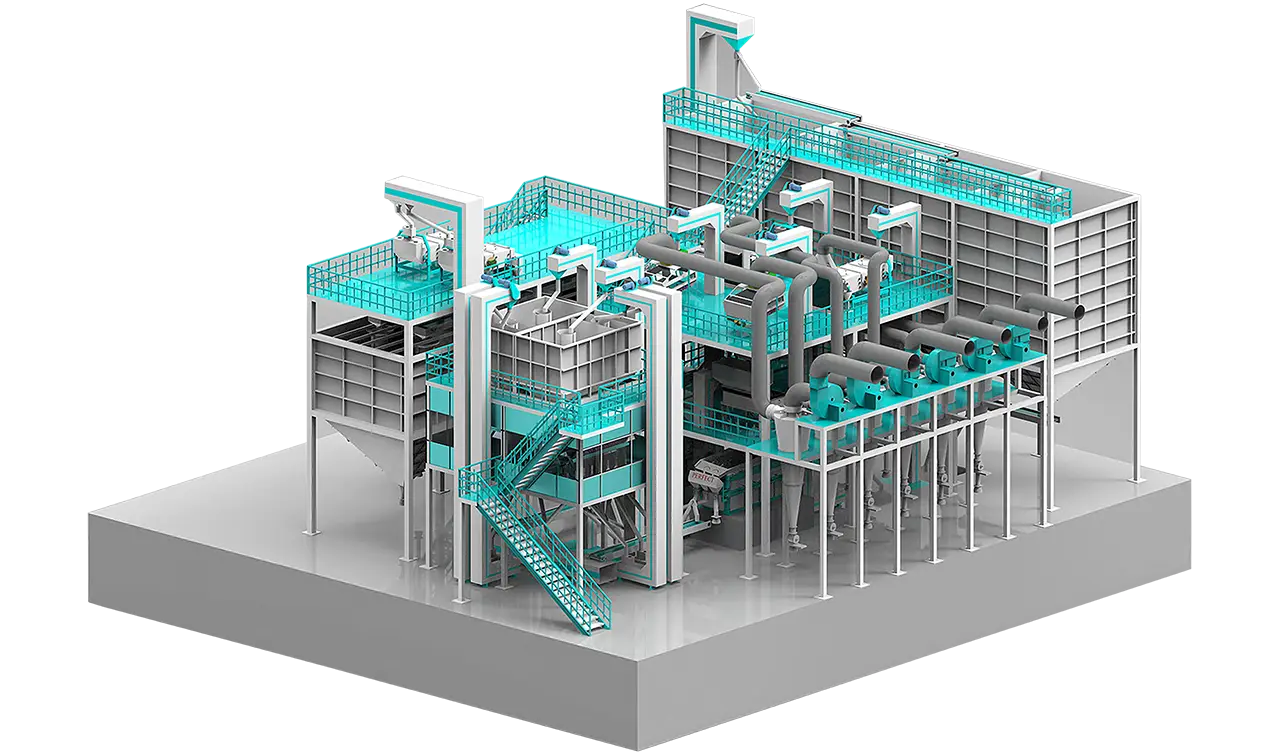

The cutting-edge Multi Commodity Cleaning Plant ensures highest standards of purity and excellence. Provides exceptional result in cleaning, suitable for almost all grains, pulses and spices. The process starts with commodity being introduced to the Classifier Machine via Elevators for primary sizing through which over size & under size impurities are separated. The commodity moves to Destoner for the removal of impurities which are comparatively denser.

Inquire Now

All these machines are equipped with an Aspiration Channel which helps to suck and blow out the dust and light weight rejections. The commodity later passes through the Magnetic Destoner for removal of metallic impurities then moves to Gravity Machine. In the Gravity Machine the commodities are separated based on their weights. Heavy material and lighter material lie in both the end and mixture of both in the center. Mix material are sent back to the machine for recycle. Final accepted material finally color sorted in Sortex Machine then graded in Grader Machine.