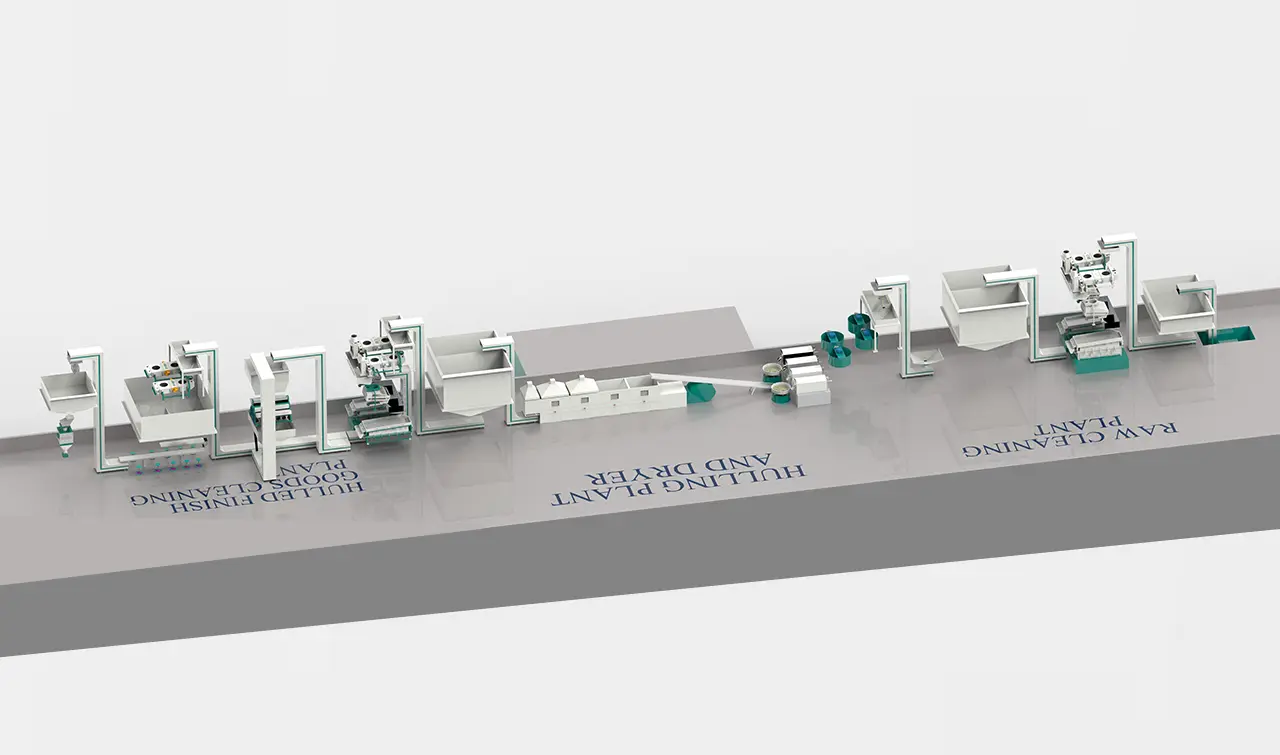

We harness advanced technology and precision techniques to deliver flawlessly hulled sesame seeds, ensuring unmatched quality and purity for our customers.” The sesame hulling process includes sequence of steps designed to remove the outer hull from sesame seeds. Initially, raw sesame seeds undergo a thorough cleaning in the Classifier machine & then in the Gravity Machine, to eliminate impurities and contaminants

Inquire Now

The cleaned seeds are then soaked in water to soften the hulls, making them easier to remove. After soaking, the seeds are drained and subjected to a dehulling process, often involving mechanical abrasion or friction techniques. This step efficiently separates the hulls from the seeds. The dehulled seeds are subsequently washed to remove any remaining hull fragments and then dried to reduce moisture content. Drying is crucial to prevent mold growth and ensure the seeds’ long shelf life. Finally, the dried seeds are sorted and graded based on quality standards, with any remaining impurities removed. The resulting hulled sesame seeds are now ready for packaging and distribution. This streamlined process ensures that the sesame seeds retain their nutritional benefits and are free from contaminants, meeting industry standards and consumer expectations.

Original

Accept