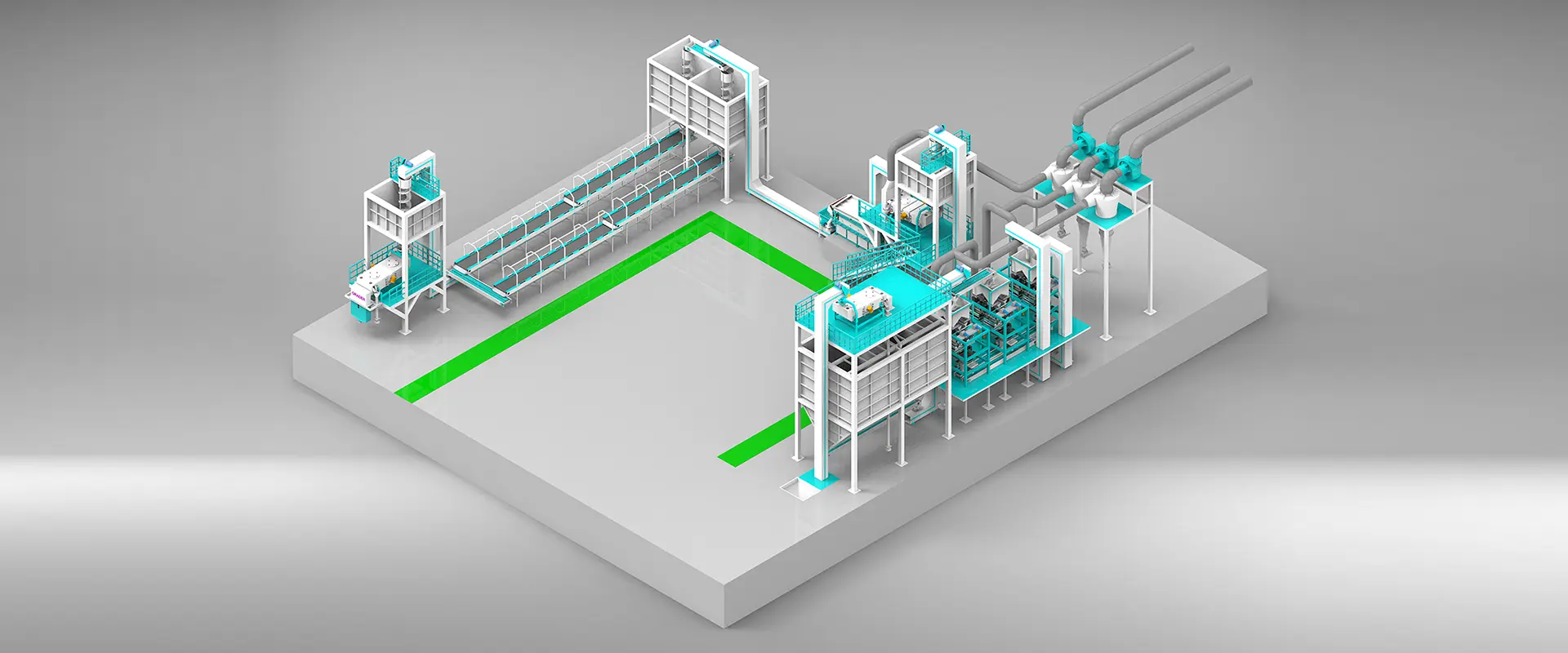

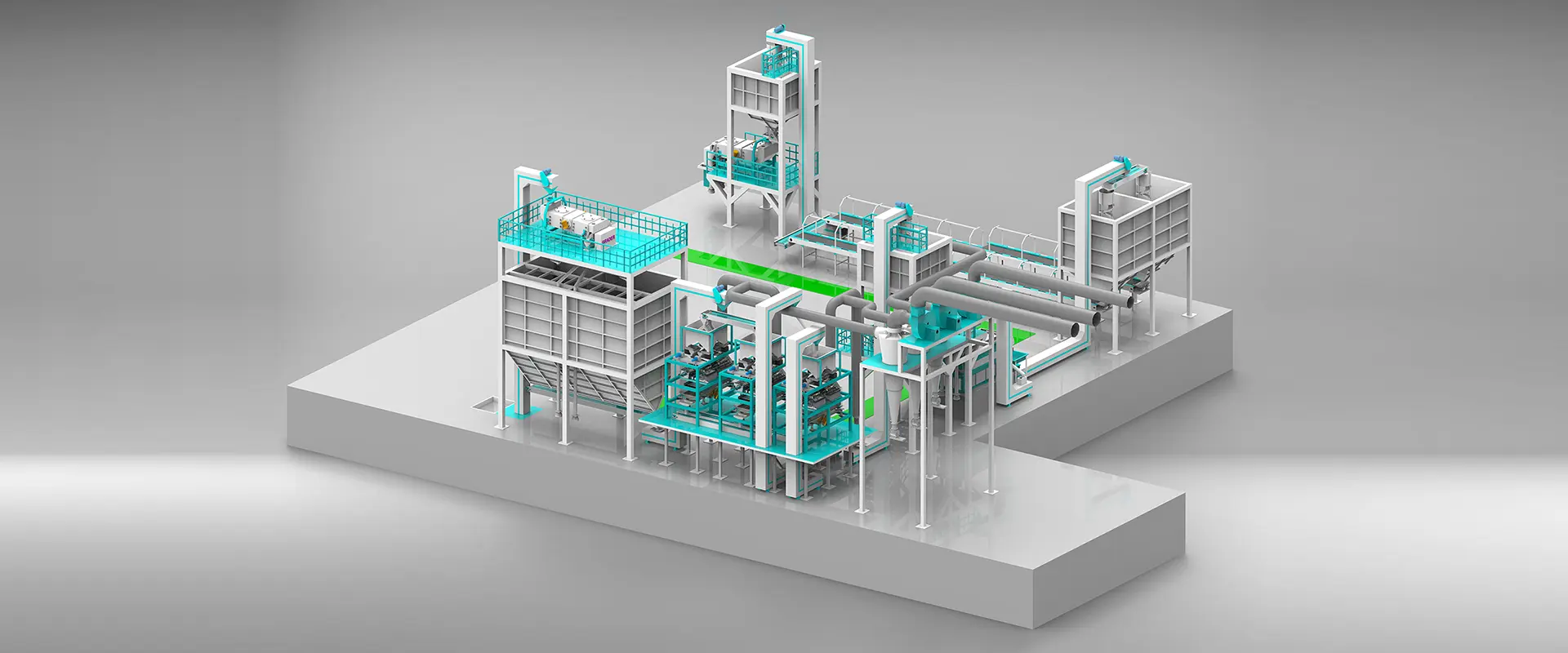

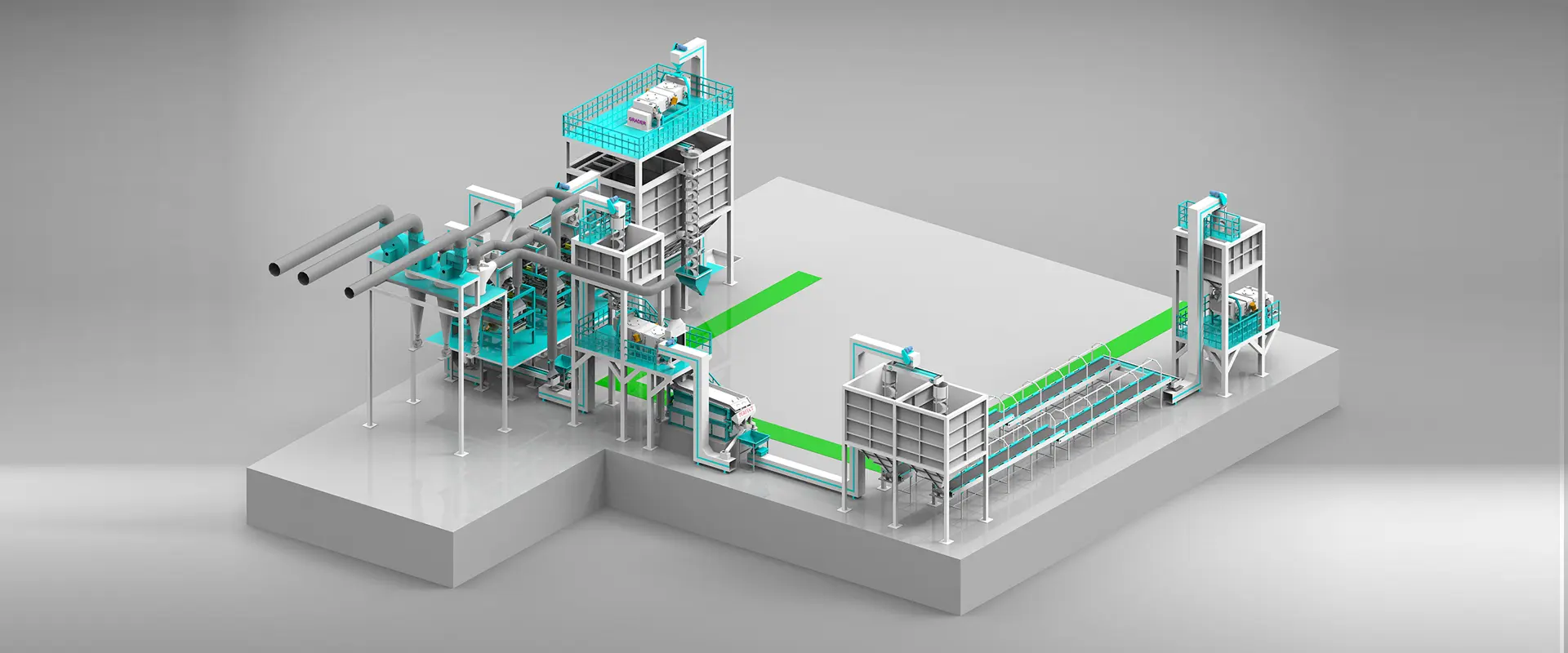

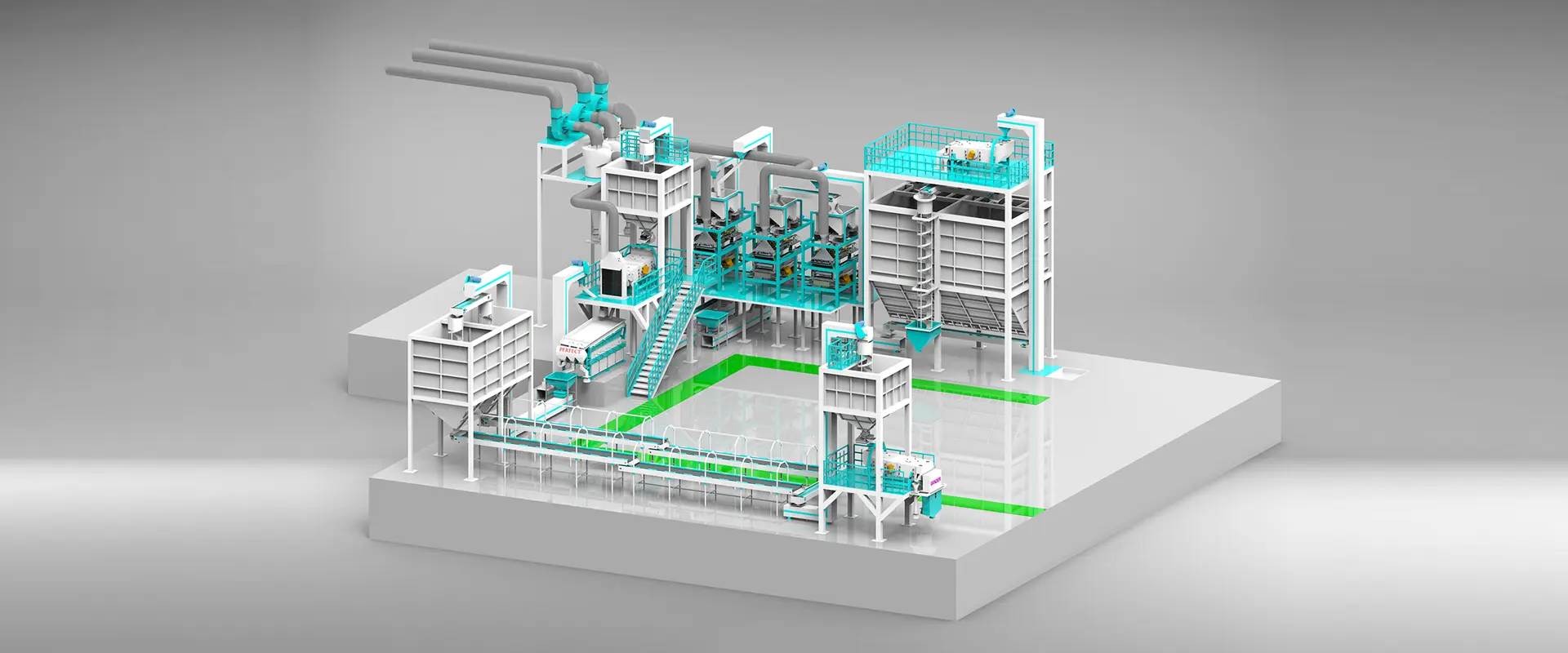

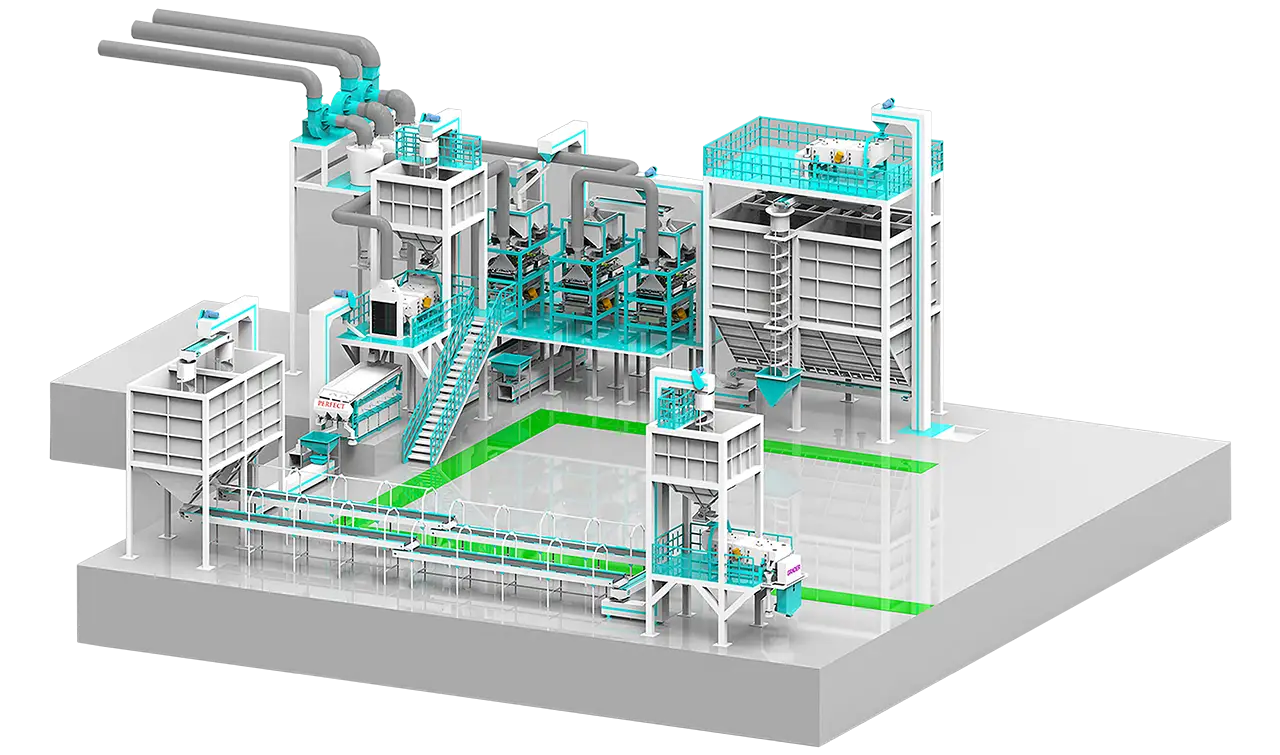

We pride ourselves on our unrivalled precision and efficiency, ensuring every almond meets the highest standards of quality and excellence. In this process almonds are first introduced to the Primary Graders which will separate the de-shelled almond kernels and inshell almonds. In the same stage only, inshell almonds can be separated based on their size. Later they are moved for cracking of the shells. Smaller and bigger uncracked almonds can be cracked either separately or together depending on the capacity.

Inquire Now

Cracking is done in two steps i.e., primary and secondary. Smaller inshell almonds which weren’t cracked in the first time, they will be fed back in the Almond Cracking Machine for secondary cracking. Kernels are collected and moved to the storage hoppers from which they are fed to the classifier. Later, Gravity machine separates the heavy and light kernels. Moving to the Manual Sorting Conveyor Belt where almonds are sorted by hand picking and then packed according to their size and grades.

Almond Raw Material

Pre Graded Raw Almond

Cracked Almond

Gravity Accept Almond

Manual Sorting

Single Tanch

Double Tanch

No Tanch

Finish Good Grades

Grade – A

Grade – B