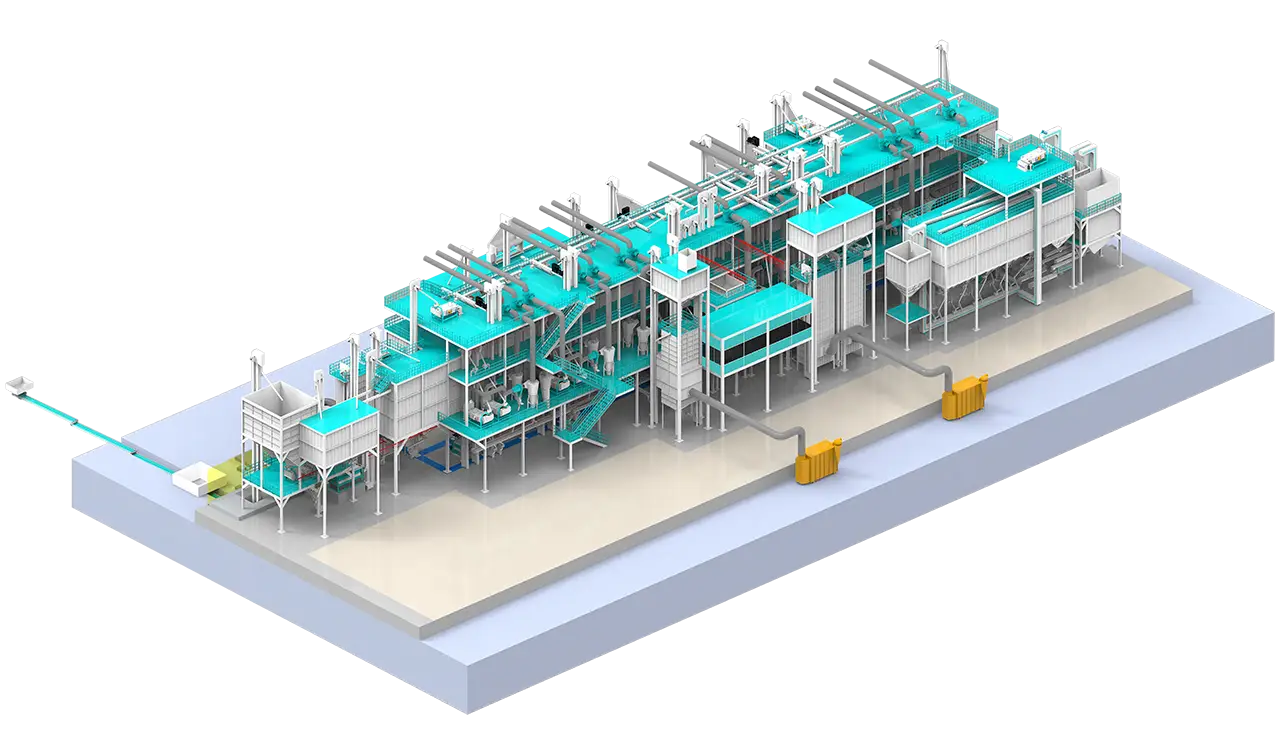

We leverage cutting-edge technology and expert craftsmanship to deliver pulses of exceptional quality, ensuring superior purity and nutritional value in every batch. Pulses are first introduced to the Classifier, Destoner, Magnetic roller then Gravity Separator Machine for Pre cleaning process. Then the pulses move forward for drying process by passing through the Dryer Machine. Afterwards the material is graded into small, medium, and bold category. Later these materials proceed for hulling in the Emery Roll Machine where the outer covering or peel of the pulses are removed.

Through Aspiration Channel hull & dust particles are blown out. Later in the process addition of oil takes place and stored for 36 to 48 hours in the storage silo. The hulling and grading will be repeated for maximum result with accuracy in the second emery roll process.

Unpeeled (with skin) pulses are now added with oil & water then stored, later go for drying and again go through third emery roll process followed by grading. After the process materials are taken for colour sorting. Pulses accepted by color sorting are moved forward for splitting process. Materials rejected after color sorting must go through fourth emery roll process followed by grading and splitting. Split dal moves forward for post cleaning and then for colour sorting. Colour Sortex accepted material go for grading then polishing & packaging.

Raw Material

Pre Cleaned

After Hulling & Splitting

Sortex Accept

Polished

Oil Application (without skin)

Chuni (Dust)

Husk

Sava

Fatka

Dankhi